86-316-6892094

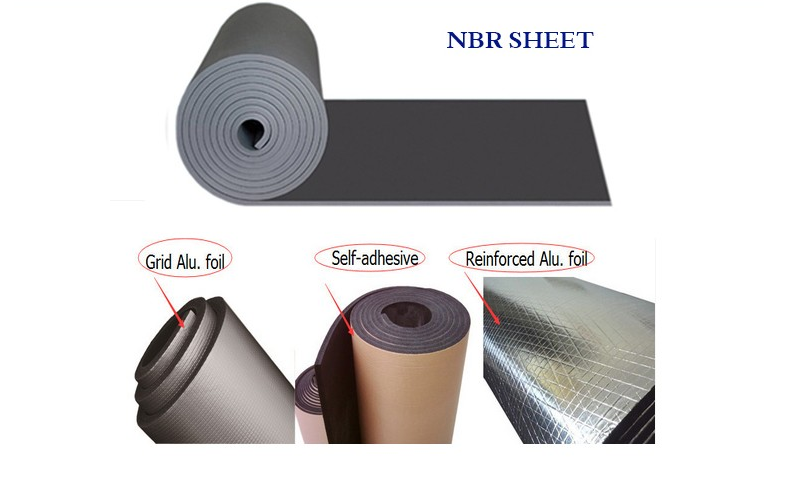

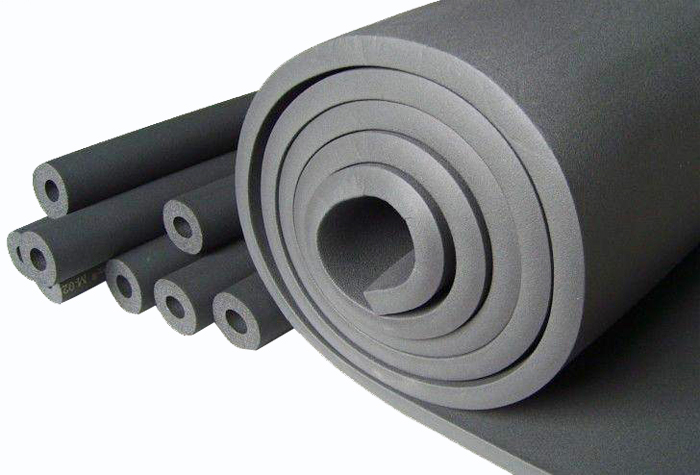

rubber foam insulation board:

Rubber foam insulation sheet are soft heat insulating, heat preservation and energy conservation materials made with advanced technology at home and abroad and advanced full automatic continuous production line imported from abroad, and through development and improvement by ourselves, using butyronitrile rubber and polyvinyl chloride (NBR, PVC) with performance as main raw materials and other high quality auxiliary materials through foaming special procedure and so on.

Facing: Sheet can be covered with aluminum foil and adhesive paper.

Advantages of Nitrile Rubber Foam Insulation Sheet:

Easy for installation; moisture resistance; Manufactured without use of CFCS or HCFCS; Excellent anti-steam permeated ability; Closed structure can effectively prevent thermal conductio.

Packing:

Packed in PE bags.

We can make OEM packing.

Applications of Nitrile Rubber Foam Insulation Sheet:

For condensation prevention and energy loss limitation where pipes and ducts, chillers and air conditioning equipment are required.

Efficiently reduces heat flow on hot systems, duct work, large piping, tanks and fittings.

Our service:

1). 7*24hours service.

2). Reply email in 10hours.

3). 10 production lines for short delivery time.

4). OEM accept.

Why choose us?

Our high performance-price ratio products and best service can bring you:

1). Good margin for your project because of our low price.

2). Good reputation for your company because the high quality of our rubber foam insulation.

3). Continuous orders from your clients because of their satisfactions.

Waiting for you contact with us!

| Rubber foam sheet(1.5M width) | |||||

| Thickness | 10MM | 15MM | 20MM | 25MM | 30MM |

| M/PC | 16M | 16M | 8M | 8M | 8M |

| Rubber foam sheet(1.2M width) | |||||

| Thickness | 10MM | 15MM | 20MM | 25MM | 30MM |

| M/PC | 16M | 16M | 8M | 8M | 8M |

| Rubber foam sheet(1.0M width) | |||||

| Thickness | 10MM | 15MM | 20MM | 25MM | 30MM |

| M/PC | 16M | 16M | 8M | 8M | 8M |

| Property | Unit | Value | Test Method | |

| Temperature range | (°C) | -50~110 | – | |

| Density range | (kg/m³) | (40~120) | ASTM D1622 or D1667 | |

| Thermal conductivity | (0°C) | (W/mK) | 0.031 | ASTM C177 or C518 |

| (40°C) | (W/mK) | 0.036 | ||

| Water vapor permeability | (kg/m·s·pa) | 1.2 X 104 | ASTM E96 Procedure A DIN 52615 | |

| Flame spread and smoke developed index | – | 25/50 | ASTM E84, CAN/ULC S 102 | |

| Class 1 & Class 0 | BS 476 part 7 | |||

| V0 | UL94 | |||

| Water absorption, by volume | % | 0.2 | ASTM C209 | |

| Mold growth | – | meet requirement | UL181 | |

| Bacterial resistance | meet requirement | ASTM G22 | ||

| Fungi resistance | meet requirement | ASTM G21/C1338 | ||

| Resistance to agent chemical | – | stable performance to agent chemical | – | |

| Ozone resistance | – | good | ASTM D1149 | |

| Aging resistance | – | 150 hours, slight wrinkles, no cracks, holes or distortion | – | |